In many companies there are a lot of processes that are often not optimally designed. Processes are often not clearly defined and there is a lack of transparency. This is where process mining comes in. This technology helps to analyse and optimise processes. In this article we will introduce you to the basics of process mining and explain how companies can benefit from it.

What is Process Mining?

Process mining is a method from business informatics for analysing processes. Data that is generated during the execution of a process is evaluated and visualised. The technology makes it possible to recognize the process steps that are actually carried out, analyse them, and optimise them through meaningful measures. Process mining is based on real data, enables real-time evaluations, and offers full transparency.

Accordingly, Process Mining offers a systematic method for visualising data related to operational business processes.

The turbo for process analysis: How does process mining differ from other process analysis methods?

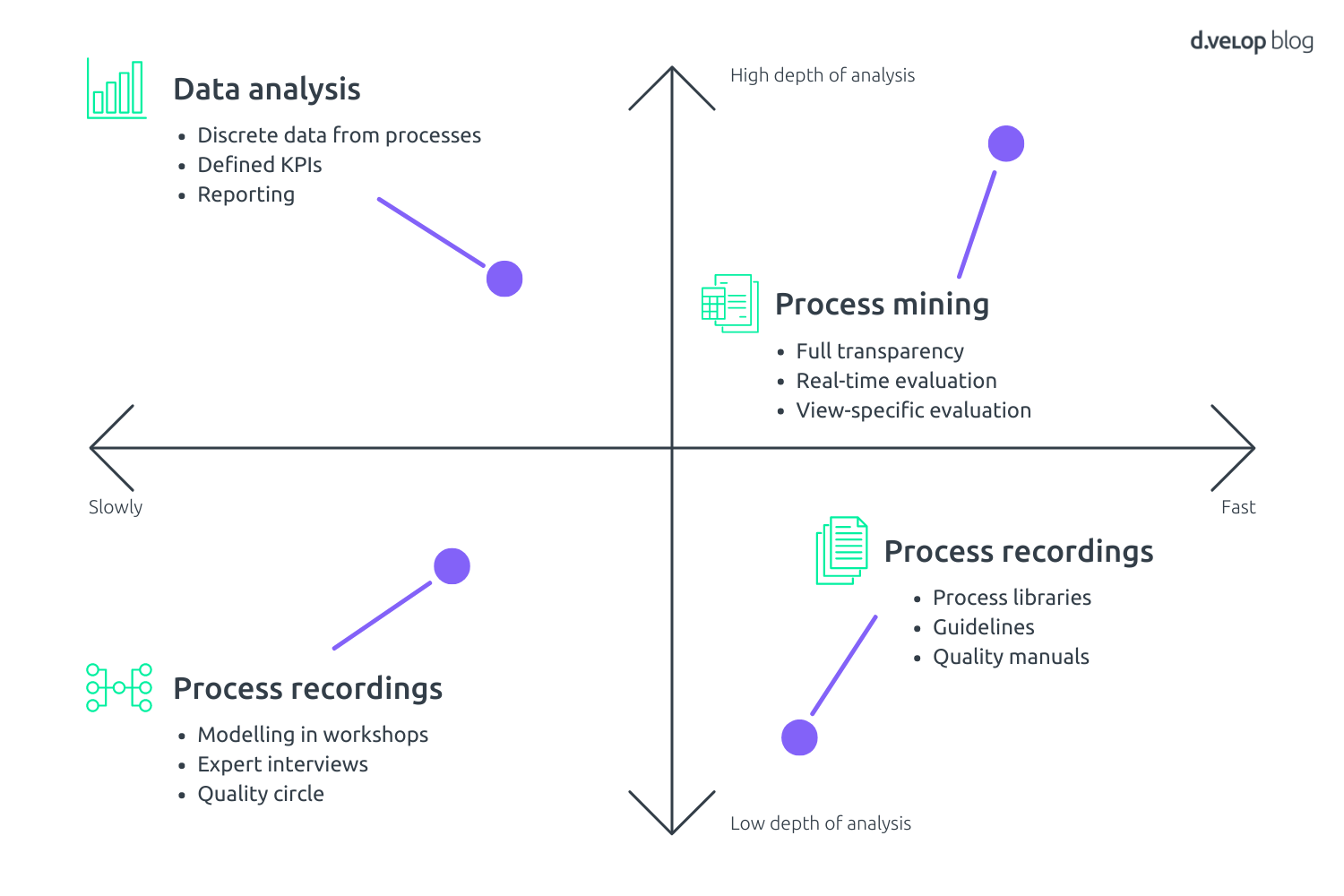

In contrast to other process analysis methods, which often rely on interviews or surveys of employees, evaluations using process mining are based on event data (#eventlogs) and provide an objective insight into the actual execution of processes.

Overall, process mining is characterised by a high level of analysis depth and speed, while methodologies are either slow or less analytical. Process mining stands out from other process analysis methods due to its data-based and systematic approach and its applicability to all types of processes.

Source: FH Münster, IPD Institute for Process Management and Digital Transformation

Another important advantage of process mining is that it is applicable to all business processes, regardless of whether they are performed manually or automated.

On the way to operational excellence: How can process mining help companies?

By objectively analysing the processes, weak points and bottlenecks can be identified, so that it is possible to see where the greatest optimisation levers lie – based on real data. This is not only exciting for users in their daily work, but data-based decisions can also be made at management level. This approach enables organisations to diagnose problems based on facts. By identifying deviations from the planned processes, active control can be carried out – where it counts.

Process mining in the analysis of the ordering process

An example of the application of process mining would be the analysis of the ordering process in an online shop. By analysing the process data, the company can identify bottlenecks or inefficiencies, e.g. long delivery times due to delays in logistics. By implementing optimisation measures, such as better warehousing or faster shipping, the processes can be optimised to improve customer service and increase customer satisfaction.

Conclusion

Process mining offers companies the opportunity to optimise their processes and thus work more efficiently. By analysing the processes, weak points and bottlenecks can be identified. Process mining helps companies to adapt quickly to market changes. Based on the analyses, customised solutions can be applied to improve the weak points. Accordingly, organisations can create operational resilience through the transparency of their processes and performance.